Now it’s time to get an accurate container temperature tracking system.

Running a cold storage supply chain is a difficult task, as it requires continuous tracking of container temperature. Your job completely relies on the temperature of the storage area because even the smallest change can lead to a big loss.

Your main role is to provide the best service. The materials, food, or medicine in your fleet should be delivered in good condition to the customers. This is not possible without providing an accurate temperature to the consignment.

What is the Container Temperature Monitoring System?

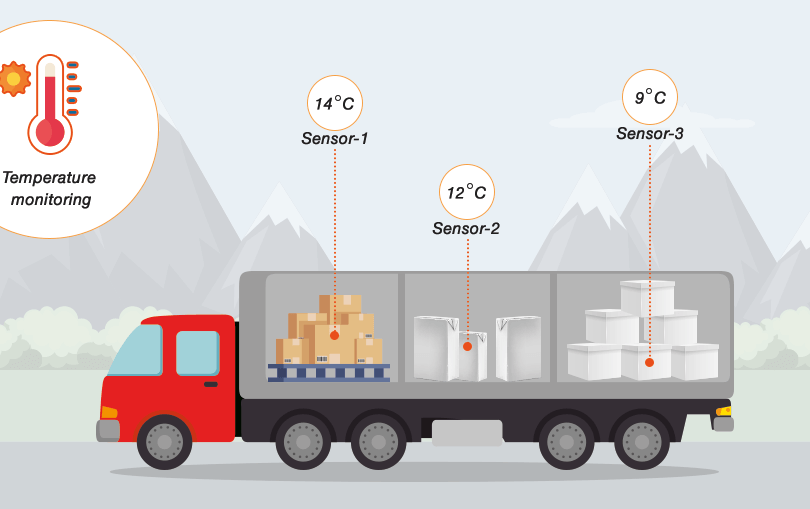

Temperature Monitoring System as its name suggests monitors the temperature changes in the storage container of the fleet and lets you know about the changes on time.

This is useful as you have the details of the temperature without stopping the fleet. It ultimately saves your time of manual temperature checking and also guards the quality of consignment your fleet carries.

How we help you with temperature monitoring?

We provide a Container Temperature Tracking System in two of our solutions, which are LogyTrak and Trakzee. LogyTrak helps to monitor the consignment and Trakzee is used in fleet management.

The container temperature tracking system checks the temperature of the storage in real time. It detects even the smallest change in the temperature.

To use this system, you will need a sensor integrated into your fleet. Then calibrate the sensor on the platform. The calibration helps the sensor know the temperature level required in the storage. Now, the system checks the temperature every 5 minutes. As soon as it finds even the slightest change, it will alert the driver and parent user.

Here, you will not only receive information about the temperature variation but also learn the location where the temperature changed.

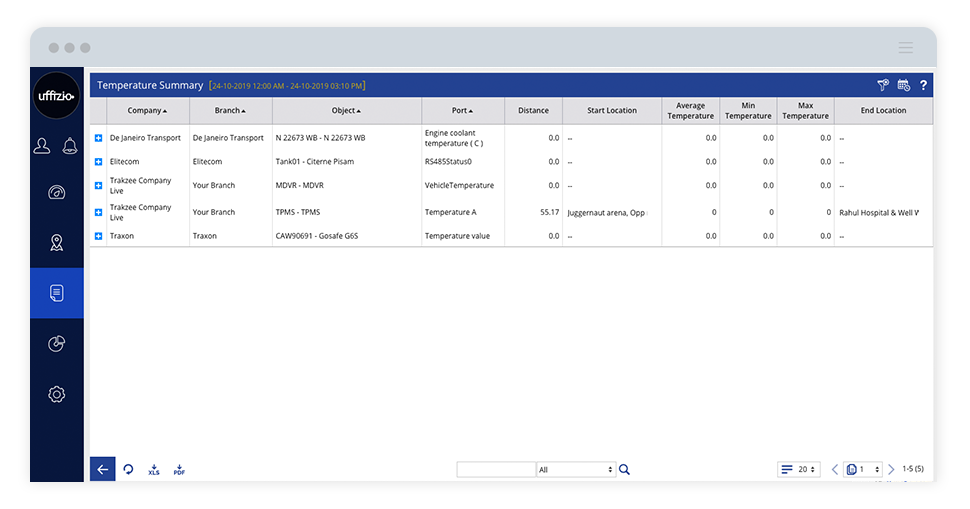

Our platforms also provide two important reports for understanding the temperature tracking during the trip. The reports are:

- Temperature Summary: This report summarizes the temperature maximum and minimum values, the changes, and other important data.

- Temperature Status: It helps the temperature value change with the exact time.

Thus, helps you detect the problems caused related to the temperature during the trip.

Conclusion

You will get a useful helping hand for your cold storage. With the well-maintained temperature, you will improve your service and thus your customers will be happier. Be connected with us to know other emerging technologies.